Optimal Design and Manufacture of

Active Rod Structures with Spatially Variable Materials

Oliver Weeger, Yue Sheng Benjamin Kang, Sai-Kit Yeung, Martin L. Dunn

Singapore University of Technology and Design (SUTD)

![]()

SUTD Digital Manufacturing and Design Centre (DManD)

![]()

Abstract:

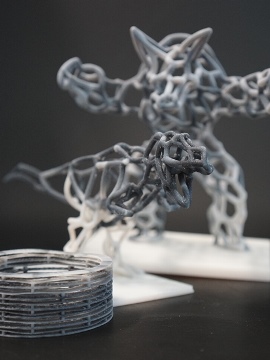

We present a design optimization and manufacturing approach for the creation of complex 3D curved rod structures with spatially variable material distributions that exhibit active deformation behavior, enabled by the shape memory effect of 3D printed photopolymers – so-called 4D printing. Our framework optimizes the cross-sectional properties of a rod structure, in particular the Young’s modulus, such that under given loading conditions it can obtain one or more target shapes resulting from geometrically nonlinear deformation, from which the structure can then actively deform back to the original shape due to the shape memory effect. Our approach includes a novel algorithm to generate physical realizations from the computational design model, which allows their direct fabrication via printing of shape memory composites with voxel-level compositional control with a multi-material 3D printer. Our design and manufacture digital toolchain allows the continuous variation of multiple active materials as a route to optimize mechanical as well as active behavior of a structure, without changing the original shape of the 3D rod structure, which is not possible with a single material. We demonstrate the entire design-fabrication-test approach and illustrate its capabilities with examples including 3D characters, personalized medical applications, and complex structures that exhibit instabilities during their nonlinear deformation.

Publication:

Optimal Design and Manufacture of Active Rod Structures with Spatially Variable Materials

3D Printing and Additive Manufacturing, 3(4), 204–215 (2016), DOI 10.1089/3dp.2016.0039

Video:

Contact:

Dr. Oliver Weeger

Singapore University of Technology and Design (SUTD)

![]()

SUTD Digital Manufacturing and Design Centre (DManD)

![]()

8 Somapah Road

Singapore 487372

Email: oliver_weeger@sutd.edu.sg

Website: people.sutd.edu.sg/~oliver_weeger